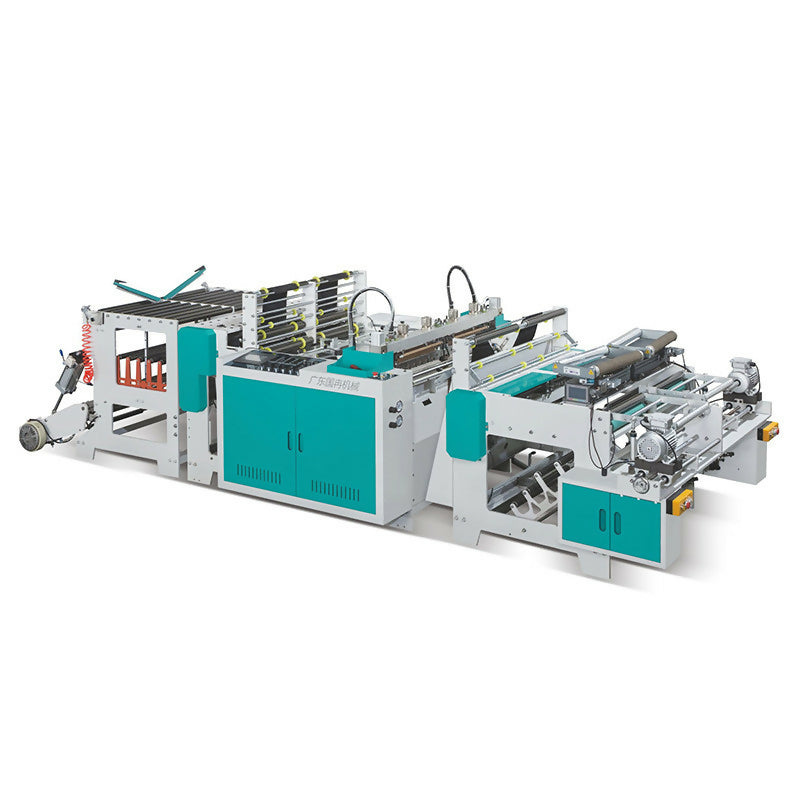

Fully Automatic High-Speed Roll Bag Making Machine

Fully Automatic High-Speed Roll Bag Making Machine

This customized bag making machine is designed specifically for producing roll-type plastic bags such as supermarket produce bags and trash bags. It features dual-lane high-speed sealing and cutting with advanced servo control to ensure precision and efficiency.

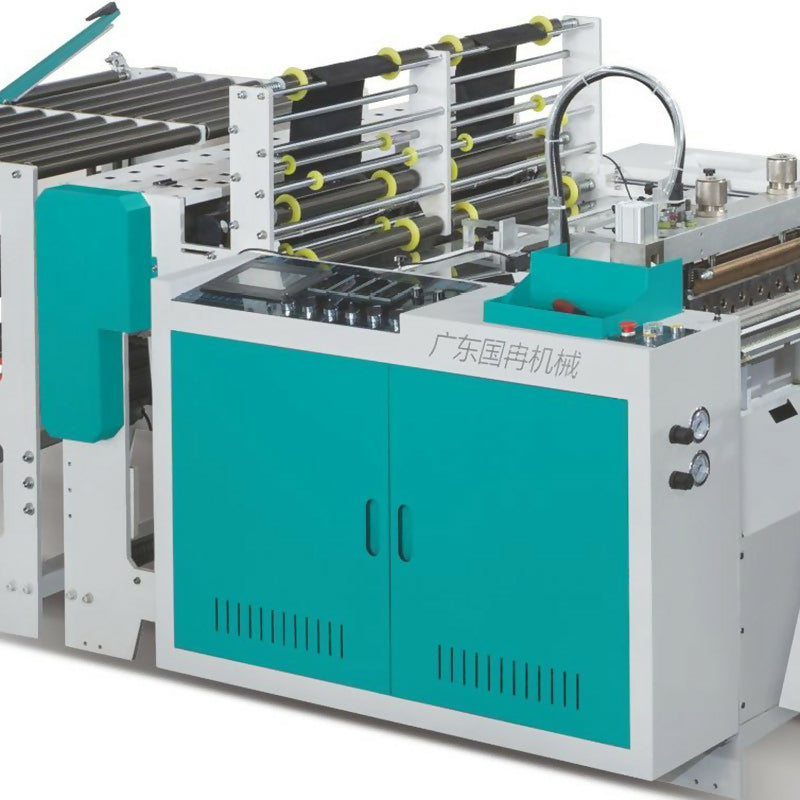

Key Features:

Application: Roll bags for supermarket use, trash bags, and flat bags.

Production Speed: 40–350 pcs/min

Sealing & Cutting Width: Max 420mm × 2 lanes

Sealing & Cutting Length: 800mm

Film Thickness: 0.008–0.016mm

Length Accuracy: ±1mm

-

Power Supply:

Main Motor: 3 kW (Huichuan servo motor)

Heating Power: 4 kW

Total Power: 15 kW

Machine Weight: 2000 kg

Dimensions (L×W×H): 5800 × 1800 × 1500 mm

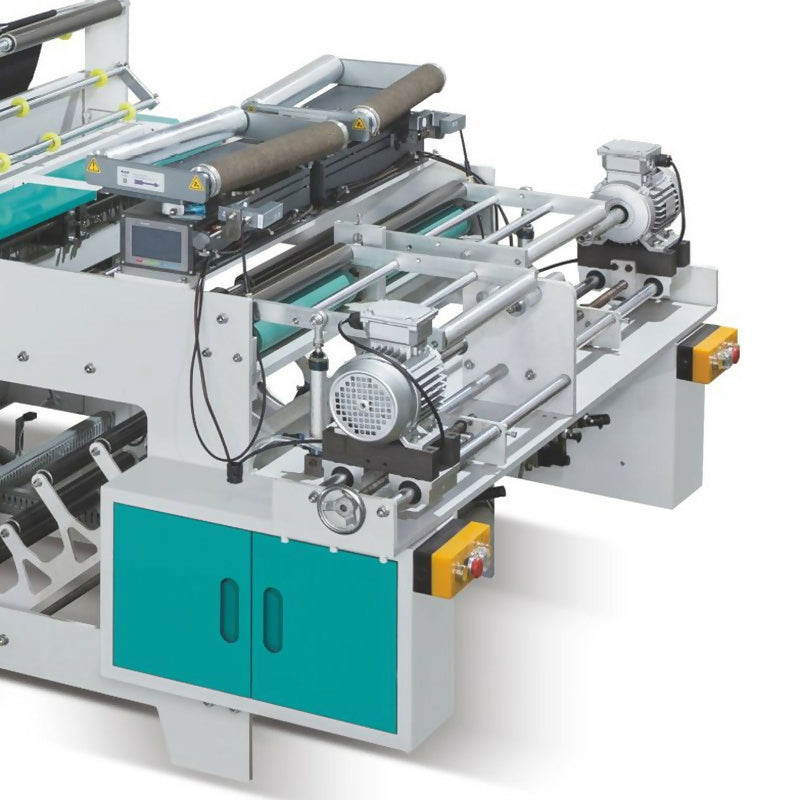

Core Components:

Frame: Reinforced steel plate structure

Main Servo Motor: Huichuan 3.6kW

Feeding Motor: Tuosu

Feeding System: Pneumatic feeding with pressure control

Discharge System: Air blow with Huichuan 0.75kW servo motor

Tracking System: Photoelectric tracking sensor (Matsushita Japan)

Temperature Control: Digital temperature controller (Yatai, Shanghai)

Heater Tube: Imported, 2000W

Cutting System: Hot knife cutting (imported blade)

Control System: Industrial computer (Wuxi-based)

Switches: Yangming solid state relay, Zhengtai circuit breaker

Bearings: NSK Japan or domestic equivalents

Inverter: Huichuan main inverter

Optional: Dual film roll deviation correction with edge sensors

Merchandising tips

Merchandising tips